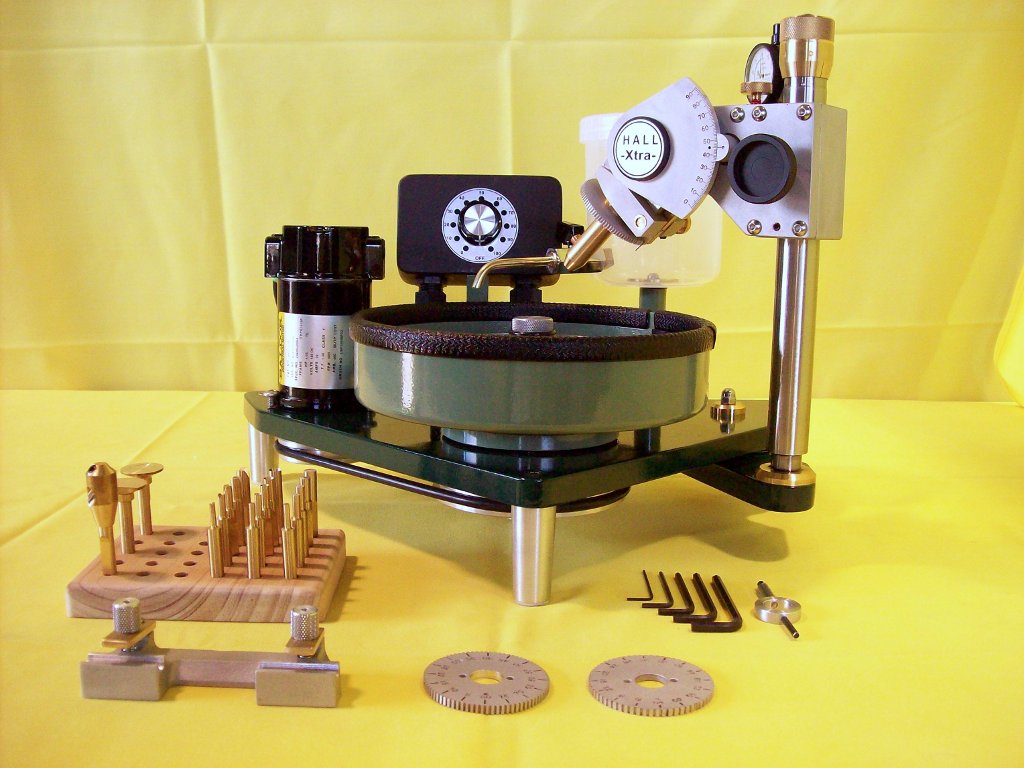

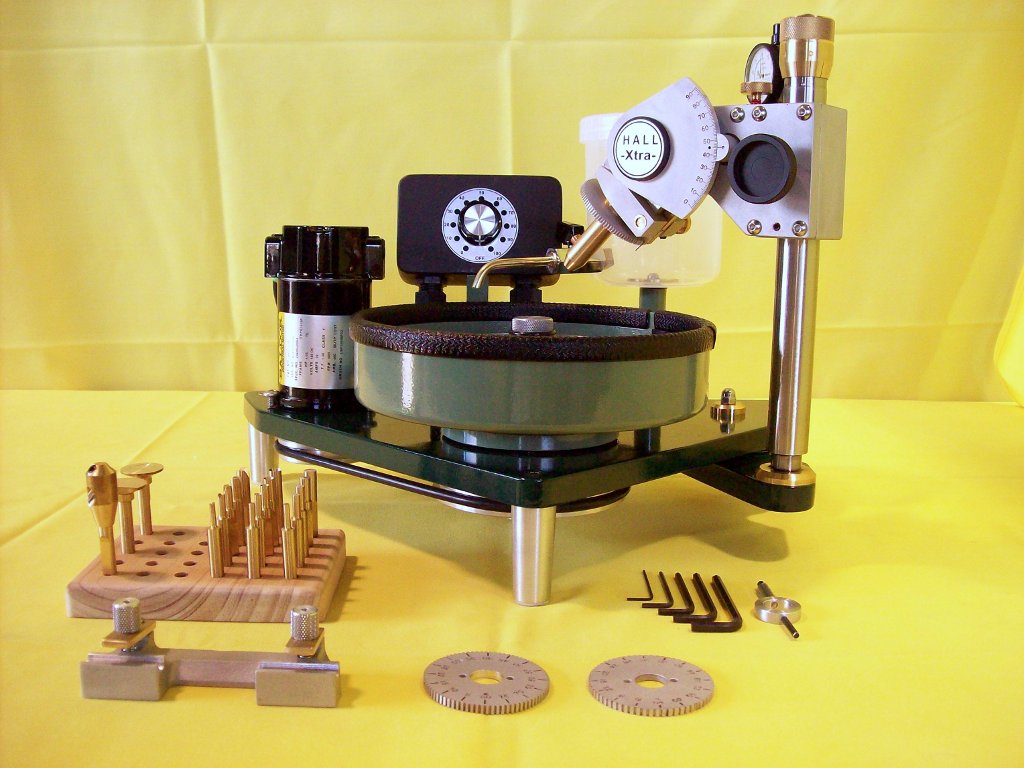

The HALL XTRA Faceting Machine.

Designed by Laurie Hall,

manufactured by UNAMIT Cairns.

Hall

Xtra faceting machine business for sale

Hall "XTRA" faceting machine

with accessories: Fifteen precision centreless ground brass dops,

half round and round master dop, 45 degree angle adapter,

high accuracy elliptical groove

transfer block, 96 tooth, 80 tooth and 64 tooth index

wheels and Allen key set.

The Hall XTRA is the result of over forty years of

continuous design and refinement which

results in a faceting machine of unmatched

performance and accuracy. The XTRA is now

manufactured by Peter Tolputt of Unamit

Cairns, who has been associated with Hall faceting

machines since 1976. The XTRA is Laurie

Hall's latest machine design and incorporates

new features not found in any previous

Hall machine to date. Accepts 6 inch lap plates only.

Features:

- Facet angles can be set to 100ths of a degree.

- Three most commonly used index

wheels: 96, 80 and 64 are included, not optional extras.

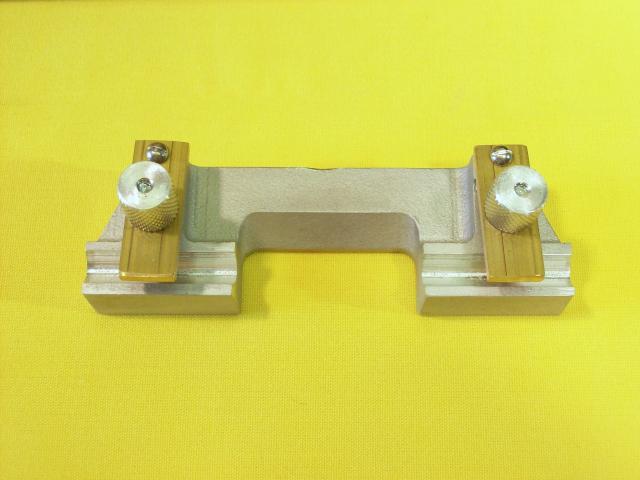

- High precision elliptical groove

transfer block.

- Easily runs off generators and any

type of mains inverter power.

- Energy

efficient, only

uses 50 Watts power maximum: the design

makes 12 Volt battery/inverter operation practical.

- Baldor USA made permanent magnet high

torque DC motor.

- Every

machine built personally in Cairns, Australia: all casting,

machining, electronics, assembly, checking and setting, packing.

- Compact, rigid, accurate,

precision built, simple and easy to operate.

Technical:

- The index wheel pin engages the

tooth in the index wheel that is in direct relation to the facet

being cut, not opposite it.

- Fine angle display of 100ths of a

degree and depth of cut indication with Mitutoyo dial gauge.

- Precision aligned mast and head

assembly with dual, preloaded quill bearing.

- Precision NSK brand preloaded,

shielded ball bearings for maximum accuracy and long life.

- Cast aluminium base and swing-arm

for low mechanical distortion and resonance free operation, i.e. does not ring like a bell or resonate during

operation or contain the high internal distortion stresses of

rolled plate aluminium.

- Centreless precision ground brass

spindle shaft enables tighter fit in the bearings than stainless

steel without seizure or any hydraulic press

distortion, giving greater machine accuracy and longer bearing life.

- New technology high efficiency

electronic motor drive for cooler motor running and jerk free lower

speeds for heat sensitive gemstone

polishing and flatter meet points.

- Wide

tolerance of voltage 200-320 Volts AC or DC and

frequency of DC-400 Hertz.

- Neoprene, seamless, vibration

free motor drive belt.

General:

Hall faceting

machines are built to the best of our ability with the equipment at

our disposal. Standard

engineering

measuring instruments; vernier callipers, micrometers, dial

indicators, engineers protractors

and straight edges,

etc. are all used to check all operations. Some operations are

dependent on the

accuracy of the

machine tools used in their manufacture. These tools are made by world

recognised manufacturers

and meet International

Limits of Accuracy. Other

measurements are dependent on human interpretation. As one

champion

facetor said: “The skill of the facetor takes over where the accuracy

of the machine leaves off, however,

Hall

machines make this easy.

Guarantee:

We will at any time,

correct any fault detrimental to the operation of the machine for

which we are responsible.

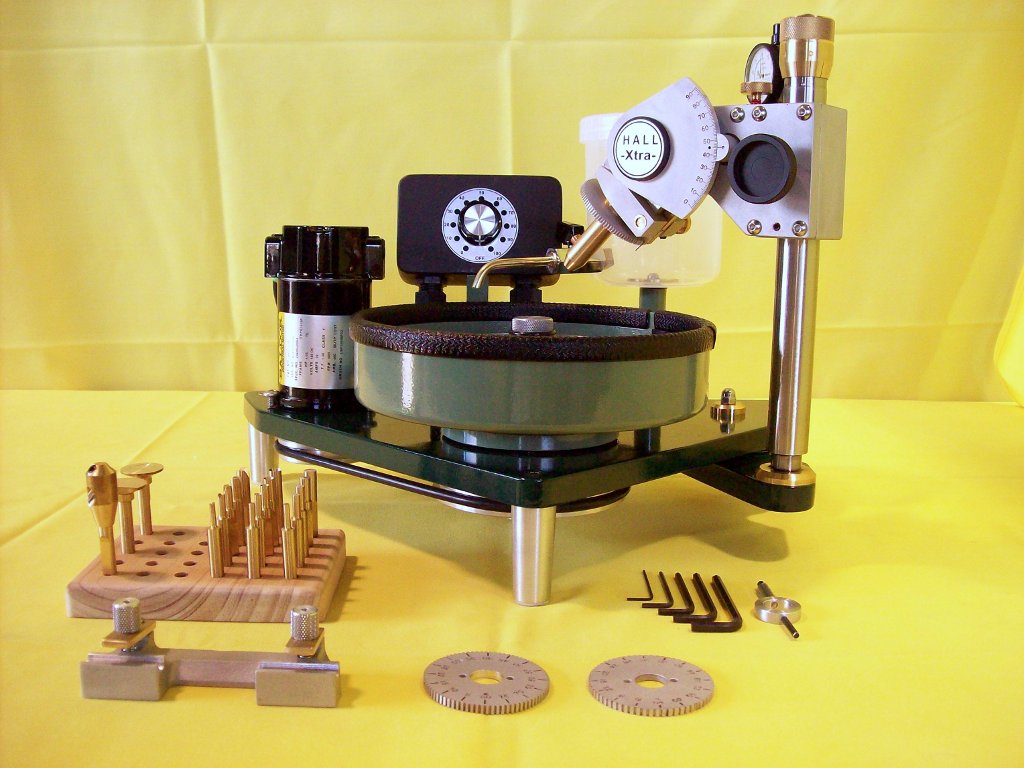

Closeup of faceting head showing the dial gauge which allows

facet angle setting to 0.01 degrees using the micro adjuster.

The dial gauge also indicates depth of cut and reads zero when

the facet is cut to the hard stop.

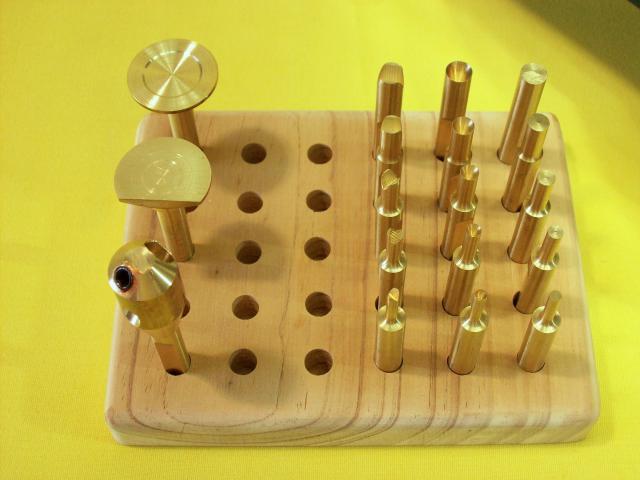

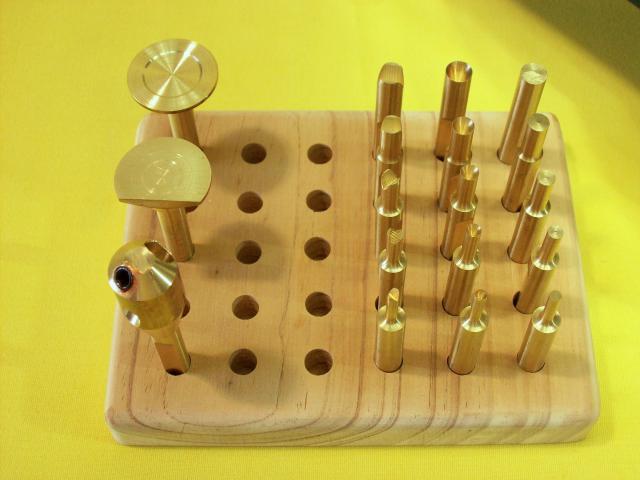

Supplied dops with every XTRA

80 and 64 index wheels (96 not shown)

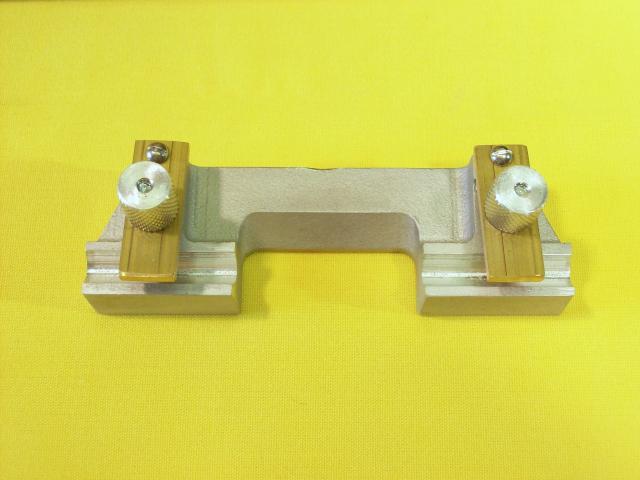

Precision transfer block

New "Xtra Plus" faceting machine

Manuals

for Hall machines

Photo

Gallery

Videos

About

Us

Contact

Us

Price

HALL

FACETING MACHINES

The choice of Champions.

Winners of National and International Faceting Competitions

The preferred machines on the Central Queensland Gemfields